Industrial Services

OK PARTS AND OK MATERIALS

FOR PRODUCTION AND TRADE

Quality testing, Sorting and Rework

Improving Product and

Supply Quality

Do supplied products or components exhibit defects? We check produced or supplied products as well as production parts and components from your supplier, we sort them and we remedy faults and defects. Our goal is to provide OK products and OK parts to ensure that production processes run smoothly, component bottlenecks are avoided and that defect-free goods are traded. In the best-case scenario, FOCUSON assures that through accurate incoming and outgoing goods inspections or by maintaining a continuous presence in the various plants.

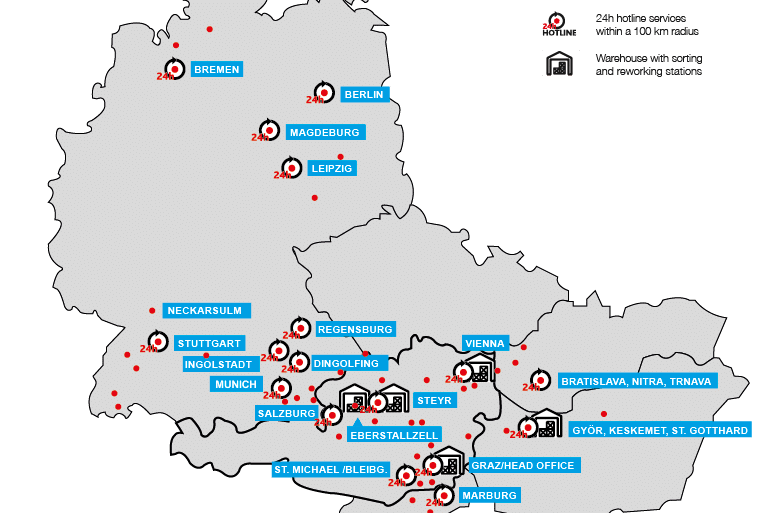

If space is at a premium, we can offer to conduct quality inspections, sorting and rework in our own factory premises. Our premises are equipped with modern testing and sorting stations. In consultation with your logistics department, we can also organise 2-way transport of your goods. Furthermore, our Online Information System FOIS 4.0 provides all important data, up to date, i.e. current working status, as well as a detailed summary covering a very wide and diverse range of evaluation options.

The decisive competitive advantage for you: Recall campaigns and complaints are reduced, and costly production downtime becomes a thing of the past. In this way, you not only improve product quality but you also greatly improve the level of service you deliver to your customers.

Services & Competencies

- Testing, sorting and reworking of materials and production components

- Volume production and quality inspections of trade goods to AQL standards

- Initial sample inspections and volume production checks

- Incoming and outgoing goods inspections

- Quality Gates and line support, 24 hours a day

- Reworking of castings with laser welding technology

- Detailed documentation - Customer portal FOIS 4.0

- External rework and sorting stations